CRF110F Technical Data

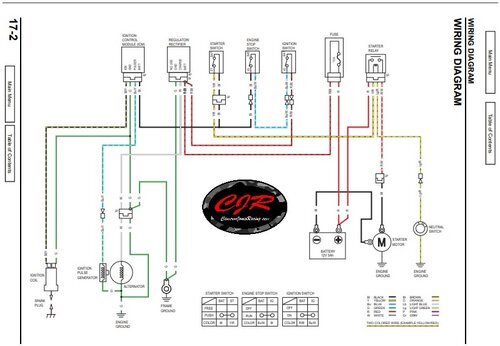

HONDA CRF110F WIRING DIAGRAM 2013-2018

Honda CRF110F Wiring Diagram

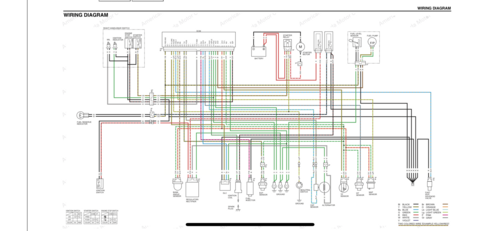

Honda CRF110F 2019 Wiring Diagram

Honda CRF110F 2019 Wiring Diagram

Honda Crf110f spec sheet 2013-2018

-

ENGINE Engine Type - 109cc air-cooled single-cylinder four-stroke

-

Bore And Stroke 50.0mm x 55.6mm

-

Compression Ratio 9.0:1

-

Valve Train SOHC; two-valve

-

Induction 13mm piston-valve carburetor

-

Ignition CDI

-

DRIVE TRAIN Transmission Four-speed with automatic clutch

-

Final Drive Chain

-

Front Suspension 31.0mm telescopic fork 3.9 inches of travel

-

Rear Suspension Single-shock; 3.4 inches of travel

-

Front Brake Drum

-

Rear Brake Drum

-

Front Tire 70/100-14

-

Rear Tire 80/100-12

-

DIMENSIONS Rake 24°25' (Caster Angle)

-

Trail 52.5mm (2.0 inches)

-

Wheelbase 41.9 inches

-

Seat Height 26.3 inches

-

Curb Weight 163 pounds (Includes all standard equipment, required fluids and full tank of fuelready to ride)

-

Fuel Capacity 1.1 gallons, including 0.3-gallon reserve

-

Ground Clearance 6.9 Inches